Here is a sample of a simple VAV Sequence of Operations (SoO)

SEQUENCE OF OPERATION

GENERAL (TYPICAL FOR 24)

The electronically controlled Variable Air Volume box (VAV) terminal unit shall be controlled from a unit mounted direct digital control unit.

A space temperature sensor shall modulate the damper between its minimum and maximum CFM set points to maintain the space temperature set point of 72ºF (adjustable).

When the space temperature rises above set point, the VAV box shall be modulated towards its maximum CFM set point to maintain the space temperature set point.

When the space temperature set point is satisfied, the damper shall remain at its current position.

When the space temperature falls below set point, the VAV box damper shall be modulated towards its minimum CFM set point to maintain the space temperature set point.

Whenever the primary air handler for the terminal unit is off or in warm-up mode, the terminal unit damper shall be positioned fully open.

Each terminal unit's direct digital control unit shall be capable of remote reset of all set points and damper position automatically or manually through the operator workstation.

When you write a sequence you need to keep in mind that your audience reading it may not be an engineer, but maybe a layperson instead. So I suggest that you keep it simple and basic and written with minimal technical jargon.

I start by reading the OEM sequence and looking at the actual configuration than adjusting the verbiage to match what is actually being installed on the job.

Team, I have relocated to New Springfield, OH, and I am serving the Ohio Valley, Youngstown, OH, and Pittsburgh, PA areas.

https://fixedusa.net/

Here are some items that have been requested recently please let me know what you would like added. My email is [email protected]

1) end-user training

2) wiresheet programing

3) difference between ball and linear valves

4) information about Visio shapes and stencils.

An Article by David Smith of HVAC.Locals.com published on January 8, 2021.

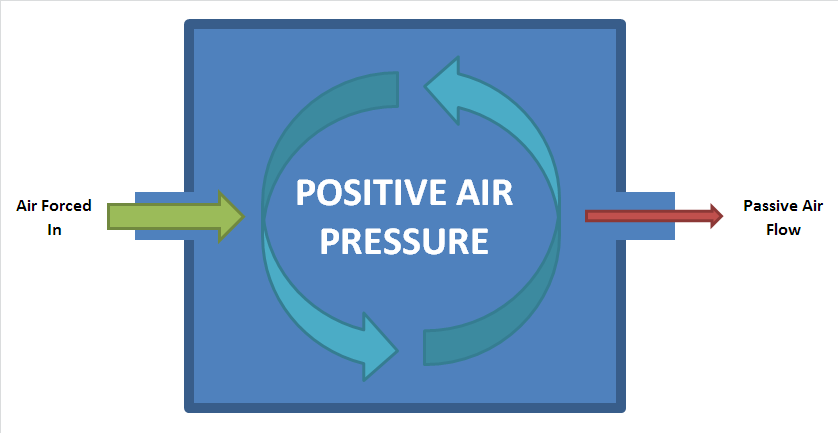

With all the use of economizers, demand ventilation, or minimum required fresh air being utilized in systems today, the possibility of over-pressurization is a real possibility.

While a slightly positive state within the building envelope is desirable in most cases, as this helps to keep dirt and odors from outside from infiltrating.

More to come soon.

Image source https://en.wikipedia.org/wiki/Positive_pressure#/media/File:Positive_Air_Pressure.png